Page 12 - Fall 2023 EDM Today

P. 12

applications. The machine uses this database to EDM Today Magazine

EDM Today Magazine EDM Today Magazine

EXPERT SYSTEM DATABASE: TECFORM

Because of the complexity just discussed, a

peculiarity of die sinking and WEDM machines is

that they contain a lot of application know-how,

canned in a huge database. This knowledge

comes from the physical laws of the process,

from the past experience and from the machining

precisely defi ne the regimes and their parameters

before the machining starts.

EDM Today Magazine EDM Today Magazine EDM Today Magazine

It is of the highest importance to start with the

best possible combination of parameters; other-

wise, the process proceeds on a path that is not

optimal, penalizing the speed, the tool wear or the

fi nal surface (or all of them).

The defi nition of every regime, and their concate-

nation (the spark energy is in principle a function

of the distance from the target position), are

computed according to the user needs:

• Type of application

EDM Today Magazine EDM Today Magazine EDM Today Magazine

•

Involved electrode and workpiece materials

Low electrode wear or highest speed

•

Lowest heat affected zone

•

Undercut

•

Final roughness

•

Required accuracy

•

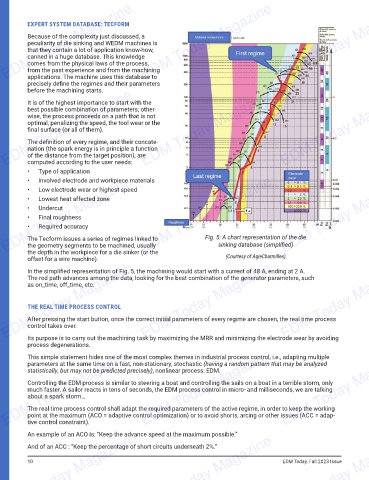

Fig. 5: A chart representation of the die

The Tecform issues a series of regimes linked to

the geometry segments to be machined, usually

the depth in the workpiece for a die sinker (or the

(Courtesy of AgieCharmilles)

offset for a wire machine). sinking database (simplifi ed)

EDM Today Magazine EDM Today Magazine EDM Today Magazine

In the simplifi ed representation of Fig. 5, the machining would start with a current of 48 A, ending at 2 A.

The red path advances among the data, looking for the best combination of the generator parameters, such

as on_time, off_time, etc.

THE REAL TIME PROCESS CONTROL

After pressing the start button, once the correct initial parameters of every regime are chosen, the real time process

control takes over.

Its purpose is to carry out the machining task by maximizing the MRR and minimizing the electrode wear by avoiding

process degenerations.

EDM Today Magazine EDM Today Magazine EDM Today Magazine

This simple statement hides one of the most complex themes in industrial process control, i.e., adapting multiple

parameters at the same time on a fast, non-stationary, stochastic (having a random pattern that may be analyzed

statistically, but may not be predicted precisely), nonlinear process: EDM.

Controlling the EDM process is similar to steering a boat and controlling the sails on a boat in a terrible storm, only

much faster. A sailor reacts in tens of seconds, the EDM process control in micro- and milliseconds, we are talking

about a spark storm…

The real time process control shall adapt the required parameters of the active regime, in order to keep the working

point at the maximum (ACO = adaptive control optimization) or to avoid shorts, arcing or other issues (ACC = adap-

tive control constraint).

An example of an ACO is: “Keep the advance speed at the maximum possible.”

EDM Today Magazine

EDM Today Magazine EDM Today Magazine EDM Today, Fall 2023 Issue

And of an ACC : “Keep the percentage of short circuits underneath 2%.”

10