Page 11 - Fall 2023 EDM Today

P. 11

Feature Article THE SERVO CONTROL

The piece of software that controls the distance

between the two electrodes, i.e., the gap, is called

UNVEILING THE EDM Today Magazine EDM Today Magazine EDM Today Magazine

“servo control.” This control loop is essential to

keep the process alive.

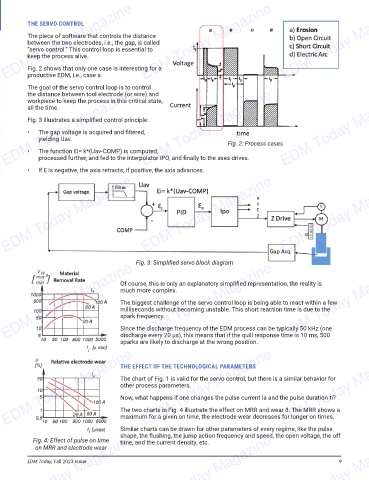

PROCESS CONTROL IN EDM Fig. 2 shows that only one case is interesting for a

productive EDM, i.e., case a.

the distance between tool electrode (or wire) and

By Marco Boccadoro The goal of the servo control loop is to control

workpiece to keep the process in this critical state,

all the time.

Fig. 3 illustrates a simplifi ed control principle:

Marco Boccadoro EDM Today Magazine EDM Today Magazine EDM Today Magazine

Marco Boccadoro has devoted his entire professional career to EDM and was honored • The gap voltage is acquired and fi ltered,

yielding Uav.

as an EDM Today EDM Pioneer. (Spring, 2013 available under the Archives tab at Fig. 2: Process cases

edmtodaymagazine.com) Mr. Boccadoro has authored or co-authored 14 patents • The function Ꜫi= k*(Uav-COMP) is computed,

covering EDM machines, power supplies, and control systems. processed further, and fed to the interpolator IPO, and fi nally to the axes drives.

• If Ꜫ is negative, the axis retracts; if positive, the axis advances.

Recently retired from his position as GF Machining Solutions’ Head of Research and

Innovation, his responsibilities included managing research projects with a network of

universities worldwide and carrying out internal research and feasibility projects.

His favorite defi nition of innovation is: “Innovation is creativity with a job to do.”

[Editor’s Note: For most users of EDM, the magic that happens to allow material to be removed is a bit of a mystery. EDM Today Magazine EDM Today Magazine EDM Today Magazine

OEM builders make the control aspects transparent to the users. In this feature, EDM Today feature editor Marco

Boccadoro gives us a fascinating look under the hood at the complexity and sophistication of modern EDM process

control. It also gives us a peek into the future as OEMs look to AI to continue to improve EDM performance.]

INTRODUCTION THE BASICS Fig. 3: Simplifi ed servo block diagram

The electrical discharge Fig. 1 illustrates

the basics of MRR

machining process takes place (material removal Of course, this is only an explanatory simplifi ed representation, the reality is

in an unstable state between rate) and wear in much more complex.

The biggest challenge of the servo control loop is being able to react within a few

open circuit and welding. die sinking EDM [1], EDM Today Magazine EDM Today Magazine EDM Today Magazine

where COMP is the

An incredible amount of servo set point. One milliseconds without becoming unstable. This short reaction time is due to the

spark frequency.

computing power on the sees that the COMP

computing and controlling value for optimum Since the discharge frequency of the EDM process can be typically 50 kHz (one

discharge every 20 µs), this means that if the quill response time is 10 ms, 500

of MRR (V) does not

plane must keep the process match the COMP sparks are likely to discharge at the wrong position.

in balance between these two value for the lowest

extremes (see Fig. 2). All this wear (ϑ).

takes place while the machine So, either one THE EFFECT OF THE TECHNOLOGICAL PARAMETERS

quietly executes its erosion task. works with the Fig. 1: Machining results as a function of the servo set point The chart of Fig. 1 is valid for the servo control, but there is a similar behavior for

lowest possible

other process parameters.

The following describes what wear (COMP=20) or with the highest MRR (COMP=43). It is like the French say, EDM Today Magazine EDM Today Magazine EDM Today Magazine

we do not see about the EDM “Wanting the butter and the money for the butter;” expressing an unreasonable Now, what happens if one changes the pulse current Ia and the pulse duration ti?

process, which is the process or unrealistic desire to have it all, or to have it both ways in a situation that The two charts in Fig. 4 illustrate the effect on MRR and wear ϑ. The MRR shows a

normally requires a choice between two mutually exclusive options.

control that is taking place maximum for a given on time, the electrode wear decreases for longer on times.

behind the scene. But, what is the servo set point? Similar charts can be drawn for other parameters of every regime, like the pulse

A few words about the gap width control, called servo control in EDM jargon, shape, the fl ushing, the jump action frequency and speed, the open voltage, the off

EDM Today Magazine EDM Today Magazine EDM Today Magazine

are needed. Fig. 4: Effect of pulse on time time, and the current density, etc.

on MRR and electrode wear

8 EDM Today, Fall 2023 Issue EDM Today, Fall 2023 Issue 9