Page 68 - Fall 2023 EDM Today

P. 68

EDM Today Magazine EDM Today Magazine EDM Today Magazine

Q

OEM

A

A

A

A

A

&

EDM Today Magazine EDM Today Magazine EDM Today Magazine

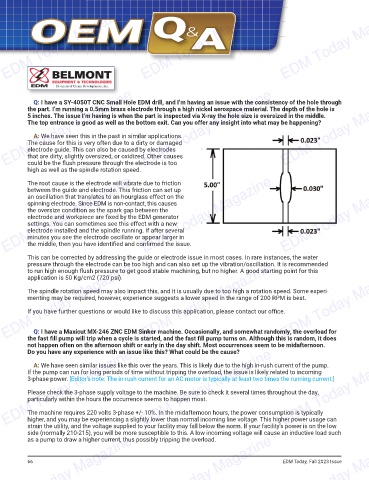

Q: I have a SY-4050T CNC Small Hole EDM drill, and I’m having an issue with the consistency of the hole through

the part. I’m running a 0.5mm brass electrode through a high nickel aerospace material. The depth of the hole is

5 inches. The issue I’m having is when the part is inspected via X-ray the hole size is oversized in the middle.

The top entrance is good as well as the bottom exit. Can you offer any insight into what may be happening?

A: We have seen this in the past in similar applications.

The cause for this is very often due to a dirty or damaged

electrode guide. This can also be caused by electrodes

that are dirty, slightly oversized, or oxidized. Other causes

could be the fl ush pressure through the electrode is too

high as well as the spindle rotation speed.

EDM Today Magazine EDM Today Magazine EDM Today Magazine

The root cause is the electrode will vibrate due to friction

between the guide and electrode. This friction can set up

an oscillation that translates to an hourglass effect on the

spinning electrode. Since EDM is non-contact, this causes

the oversize condition as the spark gap between the

electrode and workpiece are fi xed by the EDM generator

settings. You can sometimes see this effect with a new

electrode installed and the spindle running. If after several

minutes you see the electrode oscillate or appear larger in

the middle, then you have identifi ed and confi rmed the issue.

This can be corrected by addressing the guide or electrode issue in most cases. In rare instances, the water

pressure through the electrode can be too high and can also set up the vibration/oscillation. It is recommended

EDM Today Magazine EDM Today Magazine EDM Today Magazine

to run high enough fl ush pressure to get good stable machining, but no higher. A good starting point for this

application is 50 Kg/cm2 (720 psi).

The spindle rotation speed may also impact this, and it is usually due to too high a rotation speed. Some experi-

menting may be required, however, experience suggests a lower speed in the range of 200 RPM is best.

If you have further questions or would like to discuss this application, please contact our offi ce.

Q: I have a Maxicut MX-246 ZNC EDM Sinker machine. Occasionally, and somewhat randomly, the overload for

the fast fi ll pump will trip when a cycle is started, and the fast fi ll pump turns on. Although this is random, it does

not happen often on the afternoon shift or early in the day shift. Most occurrences seem to be midafternoon.

Do you have any experience with an issue like this? What could be the cause?

EDM Today Magazine EDM Today Magazine EDM Today Magazine

A: We have seen similar issues like this over the years. This is likely due to the high in-rush current of the pump.

If the pump can run for long periods of time without tripping the overload, the issue is likely related to incoming

3-phase power. [Editor’s note: The in-rush current for an AC motor is typically at least two times the running current.]

Please check the 3-phase supply voltage to the machine. Be sure to check it several times throughout the day,

particularly within the hours the occurrence seems to happen most.

The machine requires 220 volts 3-phase +/- 10%. In the midafternoon hours, the power consumption is typically

higher, and you may be experiencing a slightly lower than normal incoming line voltage. This higher power usage can

strain the utility, and the voltage supplied to your facility may fall below the norm. If your facility’s power is on the low

side (normally 210-215), you will be more susceptible to this. A low incoming voltage will cause an inductive load such

EDM Today Magazine

EDM Today Magazine EDM Today Magazine EDM Today, Fall 2023 Issue

as a pump to draw a higher current, thus possibly tripping the overload.

66