Page 100 - Fall 2024 EDM Today

P. 100

EDM Today Magazine EDM Today Magazine EDM Today Magazine

Q: We have a SY-4050T CNC Small Hole EDM machine. We have been occasionally getting a Z-axis fatal

following error. The only way to recover is to power down the machine and then power it up again. Can you help

with some troubleshooting ideas?

A: The next time this happens, check the Z-axis servo drive for an error code. We suspect you may see an error

code of 16, which is overload. This can happen if something obstructs the Z-axis, such as a large electrode getting

bound up in the ceramic guide.

Another possibility is that the Z-axis brake signal wire may be damaged. There is a simple 2-pin connector at the top

of the W-axis under the cover for the Z-axis brake. We have seen them fatigue or corrode over time. Please remove

the W-axis cover and inspect this connection.

There are other less likely possibilities. Please contact a Belmont Service Technician if this doesn’t solve the

EDM Today Magazine EDM Today Magazine EDM Today Magazine

problem.

Jeff Beyar

Machine Tool Service Manager

jeffb@belmont4edm.com | 800-356-4811

EDM Today Magazine EDM Today Magazine EDM Today Magazine

Q: We have your 656W Fast Wire EDM and we cannot get the unit to edge-fi nd or restart the program.

How can we debug this?

A: The fact that you cannot perform either task

tells us that you have committed a classic over-

sight common with these Fast Wire machines. Click

STOP(F8) on the main process screen and try re-

starting the program – see Figure 1. This will cancel

and reset your last program. If the program restarts,

you can run the edge-fi nd procedure. If the edge fi nd

continues to malfunction, check the wire pathway

and be certain the carbides are clean and the wire is

EDM Today Magazine EDM Today Magazine EDM Today Magazine

making good contact. Also, low tension can cause

the issue; ensure the tension springs are about half-

way between locked and open.

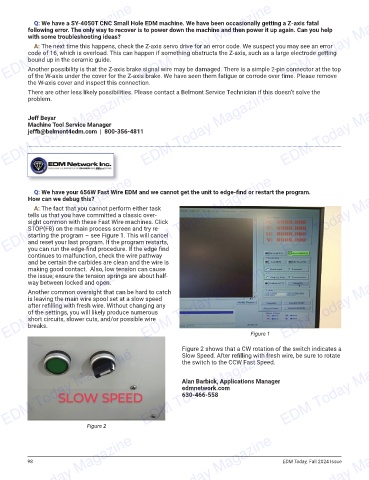

Another common oversight that can be hard to catch

is leaving the main wire spool set at a slow speed

after refi lling with fresh wire. Without changing any

of the settings, you will likely produce numerous

short circuits, slower cuts, and/or possible wire

breaks.

Figure 1

Figure 2 shows that a CW rotation of the switch indicates a

EDM Today Magazine EDM Today Magazine EDM Today Magazine

Slow Speed. After refi lling with fresh wire, be sure to rotate

the switch to the CCW Fast Speed.

Alan Barbick, Applications Manager

edmnetwork.com

630-466-558

Figure 2

EDM Today Magazine EDM Today Magazine EDM Today, Fall 2024 Issue

EDM Today Magazine

98